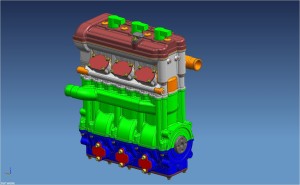

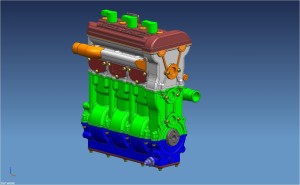

On the 9th & 10th November we were invited by UKTI (UK Trade & Investment) showcase to exhibit our compact hybrid power train at the Innovate 2015 show in London.

We met with a number of potential investors in the project and attracted a lot of interest from potential customers. Far from being a purely automotive project we found interest from companies associated with marine, off highway and military sectors, in addition to the more obvious two and four wheel road vehicle markets.

The off highway sector was particularly interesting as it wasn’t an area we had considered but the challenges of finding hybrid power trains capable of meeting the latest emissions standards appears to be more of a challenge than we had anticipated. As a result interest ranged from hydraulic platform manufacturers through to aircraft tugs and baggage handling equipment in an airport setting.

Our largest market will always be for on highway applications and we received enquiries about licensing several innovations, and associated patents, relating to optimising the transition between engine speeds that we have been working on to reduce emissions in addition to organisations interested in purchasing complete power trains.